Beginner's Corner

Table of Contents

(click on topic to go there)

- Summary

This page shares more detail than my Dust Collection Basics Blog that we should know to understand the hazards of fine dust, how fine dust behaves and how to get good fine dust collection. This page shares the assumptions most make and issues with almost all small shop air cleaners, dust collectors, and cyclone systems that leave most with a bad false sense of security. Most use equipment that leaves all looking clean while building up dangerously high levels of the unhealthiest fine invisible dust. This page translates the air engineering used by firms who guarantee customer air quality inot the simple steps required to get good fine dust protection. The other pages on this site provide the simple instructions needed to get good fine dust collection. They share information to help you choose, upgrade, set up, and maintain your shop vacuums, dust collectors, cyclones, ducting, air cleaners, tools, hoods, filters and downdraft tables to minimize your fine dust exposure. They also share detailed plans to build the solutions I use to protect my family and me.

- Assumptions

Those most in need of protection assume there is no real problem so do nothing. Most have years if not decades of doing woodworking and their friends doing woodworking with no problems other than stuffy noses. Unless we are one of the rare people who has a bad allergic reaction or get poisoned, airborne dust exposure almost never bothers us more than irritation or being stuffed up until our later years, so our personal experience says fine dust is not that dangerous. Knowing many who have worked their whole lives in dusty environments with no problems adds conviction. Those who do develop issues almost always blame other health related problems. Worse, almost all have years if not decades of being told by authority figures fine dust is not a hazard. Even government agencies who oversee worker health like OSHA used to say except for Western red cedar all airborne wood dusts are only nuisance dusts that only cause minor irritation and stuffiness. Most small shop workers and hobbyists also assume we have minimal exposure because of our limited shop time. Many also see our hand tools make almost no visible dust so assume they make little to no dangerous fine dust. Most wrongly assume our collectors that can suck up a tape measure or other small tools should easily collect the fine dust we can blow around with the lightest breath. Most also now have finer filters on shop vacuums, air cleaners, dust collectors and cyclones that leave clean looking shops, so assume they have no fine dust problem, but testing shows almost all of these systems freely pass the unhealthiest fine dust. Sadly, as you will see if you keep reading all of these assumptions are wrong.

Cal OSHA testing shows most small shops that put and vent their dust collection systems inside have dangerously high levels of fugitive fine dust that previously escaped collection. The accumulated fine invisible dust is so built up in most small shops that just walking around without making any more dust stirs enough dust airborne to fail EPA air quality tests. Cal OSHA testing also shows a few hours in almost all shops that vent inside causes more fine dust exposure than full time large facility workers get in months. This should terrify small shop workers and hobbyists because the peer reviewed medical research clearly shows the higher and longer the exposure the greater the damage. Sadly, many very popular woodworkers including television personalities who worked with the best rated dust collectors and cyclone systems available developed such serious long-time health damage from fine dust they had to give up woodworking and many were forced into early retirement. To avoid these serious problems, small shop workers including hobbyists need good fine dust protection and should have good fine dust collection. - Protection

Before you start installing good fine dust collection, please remember your goal is to provide good fine dust protection for yourself and those close to you. Good fine dust collection takes lots of planning, work and expense, but is worthwhile and not that difficult, but good fine dust protection is easy and affordable. The best protection is to wear a good respirator mask and either work outside or have a strong flow of fresh air that blows through our shops. Respirator masks need NIOSH approval and must be properly fit with dual HEPA quality cartridges. For most we get ample airflow to avoid dust buildup if we open our main doors a bit and blow a strong fan out a side door or window. Our particle counters show for best protection we need to put on our respirator mask and start our vent fan before we make dust, plus both the mask and fan must stay on for about a half hour after we stop making dust. The Doc's Orders page provides more protection detail.

- Collection

Unfortunately, it is not clear what is meant when many say dust collection. Traditional dust collection collects the dust and chips amply to keep our tools, work surfaces and floors clear of the dust that can lead to people falling, accidents, fires, and poor-quality work because dust obscures the work and markup lines. Traditional dust collection has been a requirement in many areas since the 1920s, so is well understood and what is required is very well documented. Fine dust collection provides both good traditional dust collection plus collects amply to keep the airborne invisible unhealthiest particles down to a safe level. Fine dust collection got its start in the 1950s with worries about nuclear fallout and for some it has been a requirement since the 1960s, so is also well understood and documented. Unfortunately, so many areas now require good fine dust collection that many automatically assume that dust collection means both traditional and good fine dust collection. Conversely, so many others are in areas that have no fine dust requirements that when they say dust collection, they only mean traditional dust collection. These Cyclone and Dust Collection Research web pages and my blog follow the convention of saying fine dust collection and chip collection to make clear which dust collection is meant.

- Reality

Although many would like to make what it takes to get good fine dust collection as complicated as advanced rocket science, the reality is it is pretty simple. Dust collection firms found over years of research and experience that most small shop stationary tools require about 350 cubic feet per minute (CFM) airflow to provide good chip collection which collects the visible dust and keeps our floors, work surfaces and tools clear of sawdust and chips. The major dust collection firms who guarantee customer air quality found it takes better hoods to control and capture dusty air streams and moving about 1000 CFM at these same small shop stationary tools to collect the fine dust amply to pass air quality tests. Many have a problem with needing to move 1000 CFM to pull in tiny airborne particles we can move with the lightest breath when a 350 CFM dust collector will pickup a large measuring tape with ease. they found it takes to collect the heavier visible sawdust and chips at these same tools. These same industry leaders agree that at typical woodworking dust loading levels we need at least 250 square feet of fine filter area for these 1000 CFM airflows. They further recommend to get better filter life that most use double that or at least 500 square feet of fine filter area. The best vendors use at least 600 square feet of filter area using two $300 each fine cartridge filters.

- Confusion

The biggest frustration since starting these web pages in 2000 has been the constant stream of emails from people confused by very conflicting dust collection information. To learn more on this confusion, see my research trials web page. Further, many expert woodworkers, small shop vendors, and other authorities keep adding to the confusion by sharing bad dust collection information that sounds logical but is incorrect. With dust collection meaning different things to different people many including trusted woodworking experts confuse traditional dust collection and fine dust collection. Many used to believe wood dusts except Western red cedar are only nuisance dusts and pose no health problems. Based on more current verified medical research the EPA finds all fine airborne dust so dangerous they will close down public and office buildings if the airborne dust exceeds 0.1 milligrams per cubic meter. Additional peer reviewed medical studies also show many woods contain toxic chemicals that trees produce to protect themselves and other toxic chemicals from insecticides, herbicides, preservatives, finishes, etc. When we include home construction, woodworking per the 2000 U.S. Census makes up over half of the U.S. economy. Government and private industry are terrified that if it becomes well known that woodworking poses many of the same dangers as asbestos and huge numbers have already been hurt. Woodworking remains in a many decades long war where our economy and far too many vendors would be wiped out if the dangers of wood dust become well known and documented. As a result, even government organizations are reluctant to help clear up the confusion. Fortunately, the major equipment makers who make dust collection equipment and guarantee customer air quality share exactly what their decades of testing and experience show air engineers must do to get good chip collection and good fine dust collection. That air engineering is not that complicated and is translated on these pages so you can get good fine dust protection and collection.

- Problems

Unfortunately, we cannot get good fine dust collection by using most small shop vacuums, air cleaners, dust collectors and cyclones. Not only is much of the advertised information bad, almost all of the available equipment lacks the airflows, separation and filtering needed for good collection or protection. Many small shop workers, hobbyists, vendors and even our woodworking experts get blindsided by a logical sounding but wrong assumption. We already know from using our shop vacuums this assumption is bad. Sucked air comes from all directions at once so airspeed falls at roughly 12 times the distance squared. This is why unless we put our vacuum nozzle right next to what we want to collect we get no collection. It is worse for fine airborne dust because normal room air currents will blow this dust all over unless we move enough air to pull in the fine dust before it escapes collection. The big issues are:

For years I have conducted, oversaw, and reviewed equipment tests for magazines. Our small shop magazines we used to rely on for objective tool evaluations are in a life or death financial struggle that has made most reviews far from objective. The Internet is killing magazine subscriptions and advertising revenue, so magazines don't dare offend their remaining advertisers. My last dust collection article that reported on dust collection equipment ended up with the magazine editors first deleting all the filter ratings, they then killed the article because it showed two of their biggest advertisers flagrantly lied on the separation ability of their cyclones and filters. They soon after came out with an article giving strong praise to the system our objective testing clearly showed had the absolute worst performance in the industry. Worse, not long after that they did a comparison between the system offered by one of their biggest advertisers and a small firm just getting going which had by far the best system we tested. They flagrantly lied about the poor performance of their big advertiser and said that best performing system was junk due to setup problems they caused themselves. Today, most magazine and even Internet reviews and testing are at best watered down, missing much and in many cases full of favoritism. One of my engineer friends refers to current test reporting as the best results that vendor money can buy.

With almost no government oversight and no reliable magazine reviews, many small shop vendors just lie about their shop vacuum, dust collector, cyclone, and air cleaner airflows and filtering. Vendors are in a life or death financial struggle often against far lower cost imports. For dust collection vendors most are rewarded, meaning sell equipment, based on who makes the highest claims. As a result, even the most reputable vendors to even be remotely competitive end up citing maximum performance instead of working airflows and filtering.

The reality is most small shop dust collection equipment must work against fixed resistance called static pressure plus increasing resistance as our filters get dirty. Many independent experts have tested all this equipment. They found when working against normal resistance most small shop vacuum, air cleaner, dust collector and cyclone equipment moves less than half the advertised maximum airflow.

Worse, as the filters get dirty that airflow can drop by half or more again. That leaves the reputable vendors forced to advertise maximum airflows which are about twice what their systems move in real use. Without ample airflow there is zero chance of good fine dust collection.

This fierce competition has greatly reduced the quality of most dust collection equipment sold today. A little research quickly shows almost none of the major import firms actually have design engineers on staff or even hire consulting engineers because they are too expensive. This leaves people designing dust collection equipment based on what seems logical or making downscaled copies of larger traditional designs, but many dust collection fundamentals are not logical and most dust collection equipment scales poorly. For instance, one well known tool importer used exactly the same size blower for their 1, 1.5, 2, and 3 hp dust collectors and cyclones, but since all motors turned at the same 3450 RPM speed the vendor went crazy when one of the magazine tests I ran found all moved exactly the same airflow. Similarly, my testing found the highest ranked small shop cyclone maker put out a cyclone design with a blower that moved far less air than it should have due to a poor design, used filters that freely passed the invisible unhealthiest dust, provided a cyclone whose cone plugged constantly, provided a ducting design that constantly plugged vertical runs and built dangerous piles in the horizontal runs, and in spite of the ratings sells cyclones that separate worse than typical trash can separator lids. One of our largest small shop tool vendors who sent to us a dust collector for a magazine test supplied a bigger motor and blower than the units they actually sell. They ever so carefully disguised their fraud, that they were so embarrassed when caught they came out with a new dust collector with that larger motor and blower to try and save face. The worst I saw was from a very well known and popular vendor who sells cyclones that with their ducting designs run the motor well over rated amperage resulting in our burning up three motors during testing. Of course, that never got reported in our magazine test.

All dust collectors and traditional cyclones do a terrible job of separating sawdust and push close to 100% of the airborne dust right through into our filters so our filters need to be huge or require constant cleaning. The dust trapped by our filters has razor sharp edges and points, so the more and deeper we clean our filters the faster the filter fibers get ruined and less time the filters will last. This is why on average, most full time commercial shops must replace fine filters every three months. Good fine filters that are big enough are expensive. Most small shop owners end up with 100 to 150 square foot filters which require constant cleaning and weart out very quickly. Rather than try to compete with the filters we need which cost too much, most small shop vendors instead use far more open filters then lie about how well their filters filter. Most small shop vendors now advertise fine filters but actually sell us undersized filters that freely pass the unhealthiest invisible dust particles and provide almost no fine dust protection. Our truth in advertising laws let them simply keep adding more and more dust which clogs the filter until they get whatever level of filtering they want to claim. This is legal so long as they also don't tell us the airflow at the cited filtering level. What we are not hearing is at the advertised filtering levels most small shop dust collectors and cyclones barely pass air.

Worse, too many small shop vacuum, air cleaner, dust collector and cyclone makers advertise false airflow claims. Some have made an art out of testing their blowers with no cyclones, filters or dust collectors attached, plus using special bell shaped hoods and oversized inlets that make most blowers move more than double their working airflow with these enhancements. Some make up their numbers in the back advertising rooms because these claims cannot be reproduced under any conditions. The equipment and expertise needed to test pressure is fairly simple but gets more expensive and difficult when checking airflow and even harder when testing filtering.

Filter makers set careful rules to size our filters. The finer the filter the larger the filter we need. Fine filter material is very expensive. Instead of using large enough fine filters, most small shop vendors simply copy the same sized filters used on equipment that vents outside. The units that vent outside come with very open filters that freely pass airborne dust. It takes one square foot of filter for every 10 CFM of airflow when allowing the airborne dust to blow through, but we need at least one square foot of filter for every four cubic feet of air when filtering off the fine dust. The undersized filters most small shop vendors sell constantly clog and need frequent cleaning which causes them to quickly wear out. Cleaning forces the sharp particles to cut and tear their way through our filters which leaves them too open to provide good protection.

Air at dust collection pressures behaves more like water and barely compresses, so a single restriction, any small duct, rough hose, undersized hood, or undersized port acts just like a partially closed water valve and kills airflow. In fact, we have tables that show at typical dust collection pressures we can only get 350 cubic feet per minute (CFM) through a 4" diameter duct, yet most small shop dust collection vendors sell equipment setup for 4" diameter ducting claiming airflows above 1000 CFM. At typical dust collection blower pressures it takes all 7" diameter ducting to carry 1000 CFM.

Most copy older equipment for small shop use. To comply with fire marshal and building codes almost all older equipment is placed outdoors behind fire and explosion proof barriers. Bringing this equipment inside is a double mistake. Not only do we increase fire risks and can fail insurance and building code inspections, but also this equipment was designed to let the fine dust simply blow away. When brought indoors the fine dust gets trapped inside so rapidly builds to dangerously high levels.

Most small shops only need blowers large enough to provide good collection from one tool working at a time. Small shop users use exactly the same tools as smaller commercial tools, so need the same airflow. Most small shop stationary tools require 350 CFM airflow for good chip collection and 1000 CFM for good fine dust collection. Blower technology is mature so the same size and type blower from any major blower maker will provide near identical performance. The blower tables clearly show we can get the 350 CFM needed for good chip collection from blowers sized as small as 3/4 hp, but these same tables show none of the under 3 hp dust collectors or under 5 hp cyclones move enough air for good fine dust collection when collecting from one small shop stationary tool. Cyclones need bigger blowers to compensate for the work it takes to force air in a tight separation spiral. Most small shop vendors sell dust collection equipment that lacks the airflow for good fine dust collection.

Although commercial blower technology is mature and we get near identical performance from the same type, size and speed blowers, this is untrue for small shop vendors. Small shop vacuums, air cleaners, dust collectors, and cyclones have huge differences in their quality of design and construction. Of all the top small shop vendors the magazine testing I oversaw found only Jet, Powermatic and Delta consistently had blowers that performed near comparable commercial blowers. The worst imports often moved less than half as much air in spite of having advertised performance ratings that were often higher.

Independent testing showed almost every small shop vacuum, air cleaner, dust collector and cyclone came with filters that freely passed the unhealthiest invisible dust. Most small shop vendors wrongly use and advertise outdoor filter ratings instead of industry standard indoor ASRAE filter ratings. Indoor filters are tested and rated when clean and new. Outdoor filters first build up as much dust as the filter can carry through a normal cleaning then are tested. Outdoor filters are designed to filter off the larger particles and let the fine dust go right through as it blows away and rapidly breaks down as soon as it gets moist. Over time filters build up dust trapped in their filter pores that improves their filtering, but adds more resistance. When a filter builds up as much dust as it can carry through a normal cleaning, it is said to be fully seasoned. Air engineers use fully seasoned filter ratings to properly size and know when to clean or change filters. This extra dust can improve filtering tenfold or more, but it can take a year or more for a filter to fully season in a small shop. During the seasoning time our lungs do the fine dust filtering because the fine unhealthiest dust goes right through. The finest unhealthiest dust also keeps going through our filters getting replaced at about the same rate as it passes through.

- Risks

Risks define what can happen. Most woodworkers don't amply protect themselves from injuries, fires and especially respiratory problems, so you should take the time to learn how to safely use your tools and work in your shop. Most woodworkers carry a few scars or worse that are strong reminders that even hand tools can badly hurt us if we are not very careful and take good safety precautions. Wearing proper eye and hearing protection, gloves when needed and working safely will minimize injury risks. Sawdust, chips and wood can easily catch on fire. NFPA monitoring shows on average about 1 in 1250 home based woodworking shops will have a serious fire. Most of these fires are caused when a spark lands in our tools, ducting, bags, bins, or filters then either gets quickly blown into a fire or smolders to slowly build into a serious fire long after we have left our shops. NFPA strongly recommends we put our dust collectors and cyclones outside behind fire proof walls and use fire proof metal collection bins. Building inspectors and fire marshals will cite shops and many insurance companies will not issue a policy if a shop violates NFPA guidelines. Some insurers will not pay claims if these guidelines are violated. In spite of the more serious injuries, the statistics show most woodworking injuries involve sprains, back pain, carpal tunnel syndrome, and hernia from excessive awkward bending, reaching, twisting, and overexertion or repetition. Many woodworkers also suffer hearing loss from not wearing hearing protection. Most woodworkers are regularly exposed to respiratory hazards such as harmful dust, chemicals, or fumes, and many are pretty good about wearing a respirator or mask during direct exposure, but unfortunately, the most common injury to all woodworkers is respiratory damage from fine dust. One of the better Internet overviews of the risks is printed by the United Kingdom government, Health & Safety Executive (HSE) in their Toxic Woods - Woodworking Sheet No. 30. Although these pages share many good practices, their focus is on good fine dust protection and collection.

Each fine dust exposure rarely causes more than minor short term irritation, but builds serious long term problems. By definition fine dust consists of particles that are so small that they get right by our bodies' natural defenses, go deep into and scar our lungs plus the finest particles go directly into our blood allowing them to do damage all over our bodies. Medical researchers so heavily study fine dust they call airborne dust PM short for particle material. A Google search on "PM Health Risks" turns up more than 7,000,000 references. To keep this manageable, my respiratory doctor recommends we stick with the peer reviewed medical research which has been verified by expert physician specialists before publication. The peer reviewed medical research shows every fine dust exposure causes a measurable loss in respiratory capacity, some of this loss becomes permanent, and the greater and longer the exposure, the more health damage. The peer reviewed medical research shows so much damage from all airborne dusts that the EPA, European Union, and medical experts all set really tough airborne dust limits of only 0.1 milligrams of fine dust per cubic meter of air. Exceeding these limits will result in monitored buildings being shut down and not allowed to reopen until the air quality is repaired.

Wood dusts are a particularly nasty form of fine airborne dust. Woodworking makes huge amounts of fine dust compared to how little it takes to harm our health. At a microscopic view wood behaves like a huge stack of lightly glued together fine glass tubes. When our blades, bits, cutters, or sandpaper touch wood these tubes shatter and launch airborne millions of very fine particles. These particles are covered with razor sharp edges and sharp often long barbed points. These shapes let even small air movements launch and keep fine wood dust particles airborne. So, fine invisible wood dust particles rapidly spread to contaminate all shared air. Wood dust particles last nearly forever unless they get wet. Wood dust particle shapes also damage and scar our respiratory tissues, plus cause these particles to get stuck lodged deep in our respiratory tissues. Wood dusts also contain and carry toxic chemicals that can cause eye, skin and respiratory irritation, swelling and infection, chronic cough and infections, damage our nerves and tissues with poison, build allergic reactions sometimes very quickly, and increase cancer risks. Trapped wood dust particles continue to release toxic chemicals for an extended time. The insurance data only cover large facility woodworkers. Almost all large facilities blow the fine invisible unhealthiest dust outside where it quickly breaks down when it gets wet. Even when blowing most fine dust away, woodworking makes so much unhealthy dust that the insurance data on large facility workers gives bad news. Only a tiny number of large facility woodworkers get poisoned or develop cancer, but one in seven woodworkers develop such bad allergic reactions they must stop woodworking, one in fourteen is forced into an early medical retirement, almost all lose about 1% of their respiratory capacity per year of work, and on average their lives are over ten years shorter than average.

These statistics should terrify small shop woodworkers and hobbyists, because we have much higher exposures. The medical research clearly shows the higher and longer the exposure, the greater the damage. OSHA and the various magazine tests show most small shop vacuums, air cleaners, dust collectors, and cyclone collectors capture the visible dust and blow over 15% of the dust by weight right through. Most small shop workers and hobbyists foolishly vent this equipment inside. Getting rid of the visible dust creates a bad false sense of security as we get clean looking shops that OSHA testing shows build so much fine invisible dust that most small shop workers including hobbyists get more fine dust exposure in a few hours woodworking than full time large facility workers get in months. A typical two-car garage sized shop contains less than 100 cubic meters, so just 10 milligrams of fine dust causes a typical shop to fail an EPA air quality test. This is not much dust. We get more dust than this when we slap a dusty shop apron or hand saw just over seven inches of a typical 3/4" thick board. OSHA testing shows every twenty pounds of sawdust makes 5 1/3 ounces of fine dust which is enough to cause over 15,119 typical two-car garage sized shops to fail an EPA air quality test. With our larger exposures, most small shop user and those close to us are at even greater risk. - Traditional Dust Collection

Although many would like to make dust collection sound as complex as rocket science, it is not. Traditional dust collection also known as "chip collection" improves shop safety and reduces risks by collecting chips and dust as they get made instead of having to later sweep up these debris with a broom. Chip collection keeps our tools, work surfaces and floors clear of wood dust, shavings, curls and chips to help us avoid fires, slipping, and help us better see our work. A buildup of dust and chips increases many risks which are discussed in more detail on the Medical Risks page. Fire and explosion risks are why commercial shops subject to building and fire marshal inspections must either use equipment that is certified as both fire and explosion proof or must put their dust collectors and cyclones outside behind a fire and explosion proof barrier. Cost for certified equipment is far too high for most, so almost all large facilities put and vent their dust collection equipment outside. Most small shop owners and woodworking hobbyists don't realize it, but if you have a dust collector or cyclone inside your shop, home or garage it can cause you to fail building and insurance inspections, plus some insurance policies will not pay if you have a woodworking triggered fire. Traditional dust collection has been required in some areas since the 1920s and in almost all areas since the 1960s, so what is required to get good traditional dust collection is very well understood and documented. Many small shop tools have blades, bits, cutters, sandpaper and internal blowers that generate dust filled air streams that move faster than one hundred miles an hour. Most dust collection systems only move air at around forty miles an hour. To keep the dust from being blown all over, good chip collection requires really good hoods that contain, direct and capture the fast moving dust filled air streams and ample airflow to pull in these dust filled air streams.

- Injury Risks

Keeping our floors, tools and work surfaces clear while we work is important for good shop safety. Slipping or running into a hidden moving blade, bit, cutter, or sanding surface is dangerous. You should implement good "chip collection" which means installing a dust collection system with ample hoods and enough air flow to keep our floors, tools and work surfaces clear as we work.

- Fire Risks

Small shop vacuums, dust collectors and cyclones come with plastic bags, cloth bags, plastic dust bins or cardboard dust bins to hold the sawdust and chips they collect. Many tools such as cabinet saws build up considerable dust in their enclosed spaces. Unused down drops and ducting also can build large deposits of dust. Sadly, many small shop vendors design ducting systems that don't move the air fast enough to keep our vertical runs and the larger main ducts clear so these also can fill with dust. If you watch your table saw, router, shaper and even band saw in the dark you will see that just like grinding steel, cutting wood often generates considerable sparks. If a cigarette or one of these hot sparks lands in the accumulated dust piles that build in our ducts or hoses can quickly get fanned into an intensely hot fire that can quickly spread throughout our shops. Alternatively, a spark can land in a pile or dust bin then smolder for hours before bursting into flames long after we leave our shops. You should regularly clean your tools, work surfaces, floors, ducting, and use good traditional dust collection to minimize fire risks.

- Explosion Risks

About the only time we can get a potentially explosive dust to air mixture in a small shop is when we collect large piles of fine dust. In larger shops these mixtures can be ignited with a spark from static electricity, but in small shops there is almost never enough static build up to ignite an explosion. If you keep things clean as you go to minimize picking up large piles and keep your ducting and tools grounded you will minimize risk of a small shop dust explosion.

- Injury Risks

- Fine Dust Collection

Fine dust collection became a requirement in the 1950s with a need to protect people from fine airborne radioactive particles. Fine dust collection got a huge boost from the electronics industry that had to have "clean rooms" to manufacture integrated circuits. Many areas have required good fine dust collection since the 1960s, so just like traditional dust collection, fine dust collection is also well understood and documented.

- Airborne Dust Definition

By definition airborne wood dust particles consist of particle material (PM) smaller than 30-microns that vanish without any visible trace when vented outside. For reference there are one million microns in a meter which is about 39" long, a typical human hair is about 70-microns thick and our eyes without magnification can only see particles sized larger than 10-microns. The Airborne Particle Sizing drawing on the right compares an average human hair of about 70-microns thick to 30-micron particles which is the maximum size of airborne dust, 10-micron particles which is the upper end for what we call fine dust and 2.5-micron dust particles which do the most damage deep in our respiratory systems.

By definition airborne wood dust particles consist of particle material (PM) smaller than 30-microns that vanish without any visible trace when vented outside. For reference there are one million microns in a meter which is about 39" long, a typical human hair is about 70-microns thick and our eyes without magnification can only see particles sized larger than 10-microns. The Airborne Particle Sizing drawing on the right compares an average human hair of about 70-microns thick to 30-micron particles which is the maximum size of airborne dust, 10-micron particles which is the upper end for what we call fine dust and 2.5-micron dust particles which do the most damage deep in our respiratory systems.

- Fine Dust Definition

Fine dust is also known as PM10, respirable dust and inhalable dust. By definition fine dust consists of airborne dust particles sized under 10-microns. These particles are invisible without magnification. Fine dust is so heavily studied that health researchers use more exact shorthand. They call fine dust PM10 which means particulate material smaller than (<) 10 microns, PM5 means particles sized under 5-microns and PM2.5 means particles sized under 2.5-microns. Our bodies do a pretty good job of getting rid of particles larger than ten microns, so medical professionals focus on the fine dust sized under 10-microns also known as PM10. They call this fine dust either inhalable or respirable dust because these fine dust particles slip right by our natural protections then depending on size get lodged stuck at different levels in our respiratory tissues where they cause damage and often release toxic chemicals.

- Fine Dust Properties

Particles sized under 10-microns are invisible without magnification, are so light that normal room air currents overcome gravity and keep fine dust airborne, and just about any air movement will launch fine dust airborne repeatedly. Fine dust particles behave similar to a gas or bad odor and rapidly spread to evenly fill and contaminate all areas that share airflow. This is why basement and in-home shops almost always badly contaminate the rest of our homes. Fine dust also readily travels in our hair, on our skin and on our clothes. So fine dust often badly contaminates our homes, offices, vehicles and any areas we visit. We need to be careful when still wearing our shop clothes. My own home was terribly contaminated and it only connects to my garage based shop with a self-closing well sealed door.

- Fine Wood Dust Properties

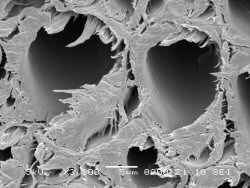

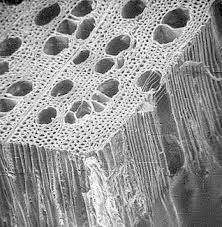

When viewed with a strong microscope wood looks and behaves like a big stack of lightly glued together fine very brittle glass tubes that can be cleanly cut as shown in the first picture. When viewed with much more detail in the second electron microscope image we see even the cleanest looking cut ends up with lots of very nasty looking pieces. Note in the third picture that these particles have razor sharp edges and sharp often barbed points. Dr. Graham Cliff who specialized in micro graphs (electron microscope pictures) said fine wood dust particles look like a glued up mess of broken tooth picks and razor blades. He also said getting pictures of fine wood dust is a nightmare job. He explained what makes them so difficult to photograph is these particles are so fine and light most get blown away when they are made so are hard to catch and hold long enough to micrograph. Another of my scientist friends says at a microscopic level working wood is similar to working a stack of glued together glass tubes with a dull axe and rocks. We know from our particle counters that every time our hand and power tool blades, bits, cutters, scrapers and even sandpaper touch wood, at the point of contact these tiny dried tubes explode into billions of fine airborne dust particles. It is impossible to do almost anything with wood without shattering these tubes and launching fine dust airborne. Our particle meters show even cutting long perfect shavings with a really sharp hand plane that makes no visible dust still launches huge numbers of fine dust particles.

When viewed with a strong microscope wood looks and behaves like a big stack of lightly glued together fine very brittle glass tubes that can be cleanly cut as shown in the first picture. When viewed with much more detail in the second electron microscope image we see even the cleanest looking cut ends up with lots of very nasty looking pieces. Note in the third picture that these particles have razor sharp edges and sharp often barbed points. Dr. Graham Cliff who specialized in micro graphs (electron microscope pictures) said fine wood dust particles look like a glued up mess of broken tooth picks and razor blades. He also said getting pictures of fine wood dust is a nightmare job. He explained what makes them so difficult to photograph is these particles are so fine and light most get blown away when they are made so are hard to catch and hold long enough to micrograph. Another of my scientist friends says at a microscopic level working wood is similar to working a stack of glued together glass tubes with a dull axe and rocks. We know from our particle counters that every time our hand and power tool blades, bits, cutters, scrapers and even sandpaper touch wood, at the point of contact these tiny dried tubes explode into billions of fine airborne dust particles. It is impossible to do almost anything with wood without shattering these tubes and launching fine dust airborne. Our particle meters show even cutting long perfect shavings with a really sharp hand plane that makes no visible dust still launches huge numbers of fine dust particles.

- Fine Dust Risks

Few realize just how little fine dust it takes to harm our health. We are constantly exposed to considerable airborne dust. Our bodies do a good job of eliminating larger airborne dust particles, but fine dust particles are bad news because they get right past our bodies' natural protections. As shown in this graphic the finer the particles the deeper into our respiratory systems they go and more harm they cause. The under 5-micron particles cause the most health damage because they go deepest into our respiratory systems. These particles get jammed stuck lodged deep in our respiratory systems where our bodies have a very difficult time of getting rid of them. Most fine dust particles, particularly fine wood dust particles have razor sharp edges and sharp often barbed points that cut, tear, stab, damage, swell and scar our tissues which reduces our airflow. The damage to the air sacs (alveoli) in our lungs builds, making us progressively more short of breath. Similar to smoking tobacco, each fine dust exposure creates such a small loss that we often do not even notice, but these losses build over time to create asthma, emphysema and chronic obstructive pulmonary disease (COPD) meaning our lungs get so damaged we cannot breathe well or get enough oxygen. This accumulated damage decreases our life spans and worsens all kinds of other diseases, mostly in our elder years. Based on the peer reviewed medical research and testing, the medical experts, the EPA, and European Union all set tough air quality standards. We make enough fine dust to cause a typical two car garage sized small shop to fail its EPA air quality test by hand sawing just over seven inches of three quarter inch thick hardwood or slapping a dusty shop apron.

Few realize just how little fine dust it takes to harm our health. We are constantly exposed to considerable airborne dust. Our bodies do a good job of eliminating larger airborne dust particles, but fine dust particles are bad news because they get right past our bodies' natural protections. As shown in this graphic the finer the particles the deeper into our respiratory systems they go and more harm they cause. The under 5-micron particles cause the most health damage because they go deepest into our respiratory systems. These particles get jammed stuck lodged deep in our respiratory systems where our bodies have a very difficult time of getting rid of them. Most fine dust particles, particularly fine wood dust particles have razor sharp edges and sharp often barbed points that cut, tear, stab, damage, swell and scar our tissues which reduces our airflow. The damage to the air sacs (alveoli) in our lungs builds, making us progressively more short of breath. Similar to smoking tobacco, each fine dust exposure creates such a small loss that we often do not even notice, but these losses build over time to create asthma, emphysema and chronic obstructive pulmonary disease (COPD) meaning our lungs get so damaged we cannot breathe well or get enough oxygen. This accumulated damage decreases our life spans and worsens all kinds of other diseases, mostly in our elder years. Based on the peer reviewed medical research and testing, the medical experts, the EPA, and European Union all set tough air quality standards. We make enough fine dust to cause a typical two car garage sized small shop to fail its EPA air quality test by hand sawing just over seven inches of three quarter inch thick hardwood or slapping a dusty shop apron.

Fine wood dusts are particularly unhealthy. More than most other fine dusts, fine wood dusts are covered in razor sharp edges and sharp often barbed points that damage our respiratory tissues and make it more difficult to clear fine wood dust from our respiratory systems. Additionally, fine wood dusts contain and carry toxic chemicals that can cause skin, eye, sinus and respiratory irritation, inflammation, rashes, sores, wheezing, prolonged colds and respiratory infections, sensitization meaning they build ever stronger allergic reactions, nerve damage, poisoning and even increase our risk of cancer. Also, fine wood dusts also often carry many other toxic chemicals from glues, finishes, fillers, insecticides, herbicides, preservatives, molds, yeasts, mildews, etc. that can be present without our knowledge and can harm our health. Molds are particularly bad as they can make some of the most toxic poisons known. Woodworkers should always check a good wood toxicity table before working any new wood and pay close attention to product warnings. Never work moldy or spalted wood without good respiratory protection. Further, because we don't know what other toxins wood may carry, we should always exercise good care when working unknown sourced woods. - Probability of Harm

We need to know both what can happen and the probability that it will happen to decide how much if any protections we need. The damage caused by fine dust depends upon overall health, genetics, type of exposure, amount of exposure, frequency of exposure, and duration of exposure. The peer reviewed medical research clearly shows the higher, longer and more frequent our exposure the greater the harm. Doctors call this a dose response relationship. The risks from fine wood dust are real and can be easily verified as most full time commercial woodworkers develop serious fine dust triggered health problems, but most small shop and hobbyist woodworkers ignore these problems because we wrongly believe our exposures are so much lower as to not be a problem. Almost all medical studies that give probabilities studied health insurance data for woodworkers in large facilities that vent their fine dust away outside. The health insurance data show at typical exposure levels for shops that vent outside 100% meaning all workers develop a significant loss in respiratory volume of roughly 1% capacity loss per year of woodworking, about 14% are forced into an early dust related medical retirement, about 7% develop such bad sensitivity (allergies) that they must permanently give up woodworking, and a tiny number develop dust related cancer. Shops that voluntarily met tougher air quality standards cut the number forced into an early fine dust related medical retirement to about half, meaning the bad news changed from one in seven to one in fourteen forced into an early dust related medical retirement.

This is really bad news for small shop and hobbyist woodworkers. Even though small shop workers often get limited shop time we get much more dangerously high fine dust exposures. Large facilities almost all blow most of the fine dust away outside where it quickly breaks down when it gets wet. When small shops upgrade their licenses, many get tested. Cal-OSHA testing shows most small shops that vent and trap the fine dust inside build such dangerously high dust levels that those in these shops get more fine dust exposure in a few hours than large facility workers get in months of full time work. Worse, air quality testing shows these dust volumes grow so high that most connected areas also become badly contaminated which with homes means near constant high exposure. The peer reviewed medical research is clear that the higher and longer the exposure, the greater the health damage. Although we found no medical studies run on small shop workers, my respiratory physician said his experience from decades of practice convinces him that small shop workers, hobbyists, our families and even our pets often suffer the most from fine wood dust triggered health problems. - Airborne Dust Life

The really bad news is most who get ill from fine dust are blindsided by the huge amounts of built up invisible fine dust. Fine dust spreads all over and goes right through our dust collection and HVAC filters. Wood gets much of its strength from silica which is better known as glass. A high silica (glass) content creates wood cells that have razor sharp edges and points that damage our tissues. Unless wood gets wet it does not pull in the organisms that break wood and silica down, so fine dust lasts as long as it stays dry. To the right is an electron microscope image of wood dust found when a pyramid was opened that had been sealed for thousands of years. Hoping fine dust simply breaks down and vanishes quickly is foolishly wishful thinking.

- Woodworking Dust Volumes

Woodworking generates a huge amount of fine dust compared to how little it takes to harm our health or fail an EPA air quality test. A typical two-car garage sized small shop is smaller than eight feet tall, seventeen feet wide, and thirty feet long for a total volume of 3,840 cubic feet of air which when multiplied by 0.0254 gives 97.54 cubic meters of air. So if we round then 100 cubic meters is larger than an average shop. The EPA will shut down public and monitored buildings if the airborne dust levels exceed 0.1 milligrams per cubic meter. Multiply our under 100 cubic meter average shop size by the EPA maximum of only 0.1 milligrams per cubic meter and a typical two-car garage sized shop fails its EPA air quality test when 10.0 milligrams (100*0.1) or more fine dust goes airborne. This 10 milligrams is only 0.00035274 of an ounce, less than a tiny thimbleful. OSHA testing shows every twenty pounds of sawdust makes on average 5 1/3 ounces of fine dust which equals 151,197 milligrams or enough fine dust to cause 15,119 typical shops to fail an EPA air quality test. Each 1% missed launches enough fine dust airborne to cause 151 typical two-car garage sized shops to fail their EPA air quality tests.

- Dust Pumps

When my air quality inspector first saw my shop he said it was one of the cleanest he had seen, but assured me it would not pass an EPA air quality test. He explained he has tested hundreds of shops that upgraded from small shop status to commercial shops, many with the same cyclone system as my shop. OSHA testing also shows most small shop vacuums, air cleaners, dust collectors and cyclone systems miss collecting at least 15% of the fine dust created by weight. Clearly, small shop dust collection equipment misses thousands of times more fine dust than it takes to fail an EPA air quality test. This fine dust that escapes collection known as fugitive dust lasts nearly forever unless it gets wet, so it builds to dangerously unhealthy levels in most small shops that vent inside. He said he could tell at a glance that my ducting was too small to provide ample collection airflow and my shop had bad hoods, plus probably a bad filter that let the fine dust escape. I did not believe him. My shop looked clean, had the best rated small shop dust collection system available with the best upgraded finest filters, and was already very well aired out because our two cars that share space with my garage based shop had regularly gone in and out for three months since I did any woodworking. His test meter showed my shop was initially fine, but just walking around stirred enough fine dust airborne to fail its EPA air quality test. Just turning on the dust collection system with no woodworking raised the dust level enough my shop failed even the fifty times easier old OSHA air quality standard. Although my cyclone was advertised to provide good fine dust collection and health protection, just sawing a few board feet of wood with the cyclone running raised the airborne dust level to as high as normal indoor air currents can carry. He again shared that Government air quality testing shows that small shop workers including hobbyists who vent their dust collection systems inside consistently get more fine dust exposure in a few hours of woodworking than workers in large facilities that vent outside get in months of full time work. Instead of providing protection my inspector called my cyclone a bad dust pump! Worse, my inspector then told me these dust levels often badly contaminate our homes where they also harm our family members and pets. Again, his meter showed my home very badly contaminated and his test kit showed almost all of that contamination was from wood dust.

- Airborne Dust Definition

- Typical Dust Collection Cycle

Unfortunately, most including me spend lots of money and take many years to go through many wasteful dust collection cycles before we finally realize we have to first become educated then do things right. There are lots of different parts and pieces to a good dust collection system.

Masks: Invariably, we then do some project that either works a wood like redwood, red cedar, walnut, etc. that leaves us all stuffed up and feeling miserable, so we buy some inexpensive paper painter's masks. These masks help, especially the better ones with the wire nose pieces and improved filters, but still at the end of the day we can pull them off not feeling good with lines of dust that show under our masks if we were sweaty. This often leads most to buying a respirator mask, and most with the dual cartridges work incredibly well compared to the paper masks. We then tend to only wear our good respirator when we are sanding as these masks are too hot, heavy and uncomfortable. Those who get into wood turning often go one step further and buy some type of powered air purifying respirator (PAPR) where a fan sucks air through a filter then blows the filtered air under a face shield. Unfortunately, most mess up both their respirator and PAPR purchases pretty badly. It turns out that most inexpensive readily available respirator masks and PAPR masks do not fit well enough to provide a good seal, are not NIOSH approved and most come with filters that are so open they filter off the visible dust and freely pass the invisible unhealthiest dust. I personally was stunned to find my very expensive wood turning PAPR face shield that most recommend had a fine filter that freely passed up to 2.5-micron sized particles which are the worst we can breathe.

Broom & Dustpan: Most start with a kitchen broom and dust pan. Eventually we most move to a softer bristled wide broom and a wide big aluminum dustpan makes a huge difference and greatly reduces cleanup time.

Vacuums: Most start with a small shop vacuum. Invariably, we find these smaller vacuums worthless at collecting from our stationary tools plus they wear out quickly if heavily used or allowed to run with the hose blocked. Almost all small shop vacuums must keep the air flowing as the air being sucked up goes through the filter then is used to cool the vacuum motor. No airflow means no cooling and the vacuum will soon be history. The bigger shop vacuums work far better with our tools and work better at cleanup, but are so noisy they are all but deafening. We also quickly get tired of a vacuum with a paper filter held on often by a rubber band. It is impossible to clean these witout creating a bad dust cloud. When we start looking to upgrade our vacuums almost all quickly get frustrated because most vendors either flagrantly lie or at least badly mislead. For instance, most larger shop vacuums claim to be as large as 6.5 hp, but a typical U.S. 120-volt 15-amp circuit will only support a maximum of a 1.6 hp motor. The problem is our vendors give maximum current draw, maximum airflow and maximum pressure, and fake advertising numbers which are all far more than these systems deliver in real use. Most have to rely on reviews and information from other shop owners to help with their selections, but most reviewers are not that well informed. This leads most into very expensive units where people tend to swear by their vacuums because they paid so much, rather than based on how well they work. Eventually most step up to an expensive high volume high pressure shop vacuum that has a large collection bin, often a switched plug that turns our vacuum on or off when we turn our connected tool on and off. These big vacuums become a vital part of our dust collection systems as they are the only way to move enough pressure and air to work with any power tool port size under about 3 inches. These high end vacuums also often cost over ten times more than our initial small shop vacuum. Most who pay for the better hoses with built in swivel ends find they no longer have to worry about hoses tangling. Even after investing this much money, most are still very unhappy as we still have problems emptying the collection bins and cleaning filters. Most vacuums are a double pain to empty, especially if we are doing something that makes lots of dust or chips. We end up with the collection bins and bags filling rapidly and often before the bin gets full, plus our filters become so dirty and dusty our vacuums barely pass air.

Vacuum Separator: Many try to address the full bin and filter problems by buying a separator lid or parts that let us convert a 5-gallon paint bucket into a separator. Also, the 5-gallon paint buckets due to their tight lid seals are more of a pain to empty than our vacuums, so most end up upgrading a few times until we get an easy to use tub with a lid that seals well such as the Gamma Seal Lid shown. When we step up from the cheap but large shop vacuums to a better quality vacuum, most have to toss the paint bucket systems. The newer vacuums run with enough pressure to push a column of water over ninety inches versus the older vacuums mostly run about half this pressure. The extra pressure sucks so hard our paint buckets collapse. Many find the better quality vacuums will suck typical paint buckets near flat. We need something tougher or reinforcement which is easily done by putting the first bucket into a second bucket. Worse, for all separator lids we still end up just as often having to clean and replace the filters!

Vacuum Cyclone: With the ongoing problem of the filters loading up, killing airflow, needing constant cleaning and frequent replacement, we start looking for options. Upgrading to a bigger fine filter helps at first, but only for a short while. Those with particle meters find they still ruin fine filters a few times a year and these bigger cartridge filters are expensive. Many then believe the nonsense advertising and then add a cyclone separator to a paint bucket type collection bin. The reported results at first make no sense because many swear all works great and others say the results are little change at all. For those who did not have separators before, they see that just like our trashcan separators almost all of the heavier sawdust and chips land in the cyclone bin instead of our vacuums, plus see the filters don't get as much larger stuff. Traditional small shop cyclone designs let 100% of the airborne dust that plugs our filters right through. Since this airborne dust plugs and ruins our fine filters, the only real benefit is our filters don't pick up quite as much of the larger sawdust and chips, but they still plug and wear out at the same rate. For all traditional cyclones we still end up just as often having to clean and replace the filters! Eventually, most realize that roughly 15% of all the sawdust we create by weight is airborne dust, and with this much dust going into our filters, we need something more. In fact, this is exactly what inspired the creation of my cyclone design which is independent medical school tested to separate the fine dust so well less than one fifth as much lands in our filters. Those who either build or buy my design from Clear Vue consistent report than filters need cleaned a fraction as much and go at least six or more times longer before they need replaced.

Dust Collectors: Most quickly learn even the best shop vacuums are still worthless at collecting from our larger stationary tools, so we buy ourselves a dust collector. Most start with a 3/4 to 1 horsepower shop vacuum that plugs into a standard single phase power outlet. The small dust collectors actually do a fair job of collecting from our stationary tools as we use them, but most rapidly tire of still having to do a lot of later cleanup because so much gets missed while we run our power tools. Meanwhile, our shops continue to be so dust filled we end up hacking and coughing with dust ruined finishes. This invariably leads to most upgrading at least a couple of times often settling with one of the better 1.5 hp dust collectors which is about as big as we can use and still use a normal power outlet. Most also add a finer bag or cartridge filter in hopes of gaining some additional health protection. Initially these finer filters appear to make a huge difference and create more airflow, but collection rapidly drops off and the fine filters become a constant annoyance as they always need cleaned.

Cyclone System: Most foolishly throw money at their poor dust collection and buy a cyclone dust collection system advertised to provide excellent collection and fine dust protection. Although many of the results are very impressive looking, we still get the same mixed results as heard from those who add cyclone separators to their small shop vacuums. Those who have never had a good dust collector or good separator are so impressed they swear their cyclones work well. Cyclones do make emptying the dust bins lots easier, but the measured results show most cyclones are bad news. All cyclones move about one third less air than the same sized dust collectors so don't collect nearly as well. It takes a lot of extra work to force air to move in a tight separation spiral and that eats up airflow. In addition to worse overall collection, our particle counters show almost all small shop cyclones greatly increase the airborne dust levels. Not only does the decreased airflow increase how much fine dust escapes collection, most small shop vendors provide more open filters that freely pass the unhealthiest fine invisible dust. Just as with the vacuum cyclone systems, other than my design traditional cyclones pump 100% of the fine dust right through into the filters. At normal woodworking airborne dust levels, filters fine enough to protect our health quickly clog, need constant cleaning, and wear out very quickly. On average full time commercial shops must replace their fine filters on their cyclone systems every three months of full time woodworking. Competition for small shop woodworking dollars is beyond fierce, so many small shop vendors compromise and use more open filters that get rid of the visible dust so filters last much longer but the unhealthiest fine invisible dust passes right through.

Air Cleaner: We continue to be frustrated by the constant problems with dust settling overnight, covering our floors, work surfaces, and tools, and ruining our finishes. Many also find fine dust irritating and develop mild allergic reactions or we get concerned about the hazards of fine invisible dust. This inspires many to add a ceiling mounted air cleaner thinking that these will stop the ruined finishes and protect our health. Unfortunately, like exhaust fans air cleaners work far too slowly to protect our health, but they do protect our finishes by getting rid of the constant overnight buildup of visible dust on every surface.

Fine Filters: The advertised fine filters for most air cleaners, shop vacuums, dust collectors, and cyclone systems provide a bad false sense of security. Filter material fine enough to protect our health is very expensive, yet competition to sell small shop equipment is beyond fierce, so few vendors are willing to include filters that are large and fine enough to provide good health protection unless they are an expensive upgrade option. As a result, most small shop dust collection equipment comes with more open filters that filter off the visible dust and leave clean looking shops, but in spite of advertising claims freely pass the unhealthiest invisible dust.

Particle Counter: Eventually, the more serious woodworkers and those who start having respiratory problems and allergic reactions realize that they need serious help because the fine dust that harms our health is invisible without magnification and does not settle enough overnight to be visible or harm our finishes. It also is so fine and light is spreads to all shared air. Rather than continue to guess about the status of their shops and connected areas, many choose to work with a good particle counter such as the Dylos Products Pro logging particle meter. Almost all find if they vent their traditional dust collection equipment inside invariably even very clean looking shops build up so much fine invisible dust that just walking around stirs up enough dust to fail an EPA air quality test. These meters show most small shop dust collection equipment cleans up the visible dust while acting as bad dust pumps that freely pass, stir airborne and circulate the unhealthiest fine invisible dust.

Sadly, most have to develop either breathing problems or allergies before they get serious about providing good fine dust protection. The really sad part of all this is it really is easy to get good fine dust protection and not even that hard or expensive to get good fine dust collection. -

Minimum Protections

Over half of my email comes from small shop woodworkers who all ask a similar question, “How can I get good fine dust collection in my small shop without lots of expense?” The answer is simple, but not what most want to hear.

Unlike good fine dust collection, you can easily get good fine dust protection without much work or expense. A mask and good cross ventilation works and provides good protection. To protect yourself you need to wear a good properly fit dual cartridge filtered NIOSH approved respirator mask that goes on before you start making dust even if you don't use power tools plus you need to run a strong fan in an open side door or window with your main door open so you have good cross flow ventilation. I use a 3M 7500 series respirator mask and a commercial 24" fan blowing out a back door with my main shop door open three to five inches. You can clean up with a broom and dust pan, leaf blower, compressed air line, shop vacuum, dust collector, or cyclone, but our particle counters show the mask and fan need to stay on for about a half hour after you stop making dust and stirring the dust from your clean up to get your shop air back to outside air quality. Then you can take your mask off and turn off the fan. -

Good Dust Collection

Good dust collection requires more work and expense, but is equally doable. The major dust collection firms who guarantee and test air quality have spent decades studying and refining their dust collection techniques. They break dust collection into two different parts, traditional dust collection which is often now called chip collection and dust collection which now means chip collection plus controlling the fine airborne dust. This unfortunately causes lots of confusion because it makes it difficult to tell if a vendor is referring to fine dust collection or chip collection when they say dust collection. I try throughout my pages to keep this clear by stating either chip collection or fine dust collection.

-

Chip Collection

Good chip collection keeps our floors and tool surfaces clean to minimize fire, slipping and other injuries, plus it makes it easier to work when we can see our cut lines, plans, etc. Until the 1990s dust collection for woodworking meant chip collection which collects the same dust and chips we would otherwise sweep up with a broom. This type of dust collection has been a U.S. requirement since the 1920s so is well understood. We know we must have tools with hoods that control, direct and collect most of the sawdust and chips with ample airflow to pull in the material, transport it through our ducting, then get rid of it.

Most commercial shops subject to either building or fire inspections must follow the dust collection standards set by the National Fire Protection Association (NFPA). These NFPA codes require either use of very expensive dust collection systems certified to be fire and explosion resistant or that dust collection systems be put outside behind appropriate fire and explosion proof barriers. The cost for fire and explosion proof equipment is so high that most large woodworking facilities put their dust collection systems outside.

Most large commercial woodworking facilities also vent outside because it is safer and less costly than filtering. The problem is woodworking just makes far too much airborne dust that quickly loads up and ruins fine filters. OSHA testing shows airborne dust makes up roughly 5% of the total weight of sawdust made. This does not sound like much, but it only takes a little airborne dust to plug fine filters. Plugged filters kill airflow causing our dust collection systems to work poorly. This means fine filters need constantly cleaned, but cleaning quickly ruins fine filters. Airborne wood dust particles have razor sharp edges and sharp often barbed points. When we clean by shaking, vacuuming, or blowing, these razor sharp edges cut and tear their way through the very fine filters strands. Soon our filters no longer provide fine filtering. Most commercial shops that use fine filters have to replace their filters every three months of full time woodworking. Most large woodworking facilities instead use fairly open filters or cyclone separators to remove the heavier sawdust and chips then vent their airborne dust away outside. When blown outside into normal outdoor air currents airborne dust particles vanish with no visible trace and quickly break down when they get damp.

Good chip collection also requires good tool hoods. The problem is our blades, bits and cutters launch the dust and chips too fast. For instance, a normal 10" diameter table saw blade launches dust at over 100 miles an hour yet most dust collection systems only move air at about 45 miles an hour. Without good hoods that control and capture these fast moving air streams we will not get good collection. The good news is the dust collection community shares many excellent hood recommendations and designs for almost every type and size of tool. The bad news is most existing small shop tool hoods need reworked to be effective.

We can fairly easily get good "chip collection" for most small shop stationary tools by moving about 350 cubic feet of air a minute (CFM). To move this much air, we need at least a 1 hp dust collector but are better off with a 1.5 hp. Unlike vacuum cleaners that move air at high pressures, dust collectors move air at much lower pressures. At these lower pressures air is more like water and will barely compress. Any small diameter duct, fitting, or restrictive flex hose will act just like a partially closed water valve and greatly restrict flow. To move our 350 CFM airflow, we must have at least 4" diameter ducting and smooth interior walled flex hose. -

Fine Dust Collection

Good fine dust collection collects from out tools well enough that we maintain safe air quality. Unlike indoor air quality which is regulated according to medical peer reviewed standards, woodworking air quality has been a political hot potato for decades with many different standards. By 1989 there were three different standards, the EPA indoor air quality standard which was near impossible for commercial woodworking shops to maintain, the five times easier ACGIH standard, and the fifty times easier OSHA standard. It turns out that the solutions to meeting each of these standards is identical except each tougher standard requires moving more air. The OSHA standard got thrown out completely as unsafe, so now most larger facilities voluntarily comply with either the ACGIH or EPA standards. Many decades of research and experience shared by those firms that guarantee customer air quality shows what we must do to get good fine dust collection. They found woodworking makes so much dust that exhaust fans and air cleaners cannot lower the airborne dusts levels fast enough to keep from failing air quality tests, so the only way to ensure passing air quality tests is to collect the fine dust as it gets made. Collecting the fine dust as it gets made is work but well understood. They learned woodworking makes huge amounts of fine dust compared to how little it takes to have unsafe air and fail an air quality test. Their measurements show because woodworking makes so much dust and it takes so little airborne dust to be unhealthy, air cleaners and exhaust fans cannot pull the dust levels down fast enough to keep from failing our air quality tests. They found once fine dust escapes collection normal room air currents rapidly spread this dust to evenly fill any attached space just like a bad odor plus fine dust is easily transported on our clothes, hair and skin to contaminate other areas. Fortunately, these firms have shared exactly what we need to do for good fine dust collection. Their secret is they capture the fine dust as it gets made. This requires the following.

They found the biggest problem is just like with chip collection. Unless we totally enclose the dust producing areas of our tools, we need hoods that block and control the fast moving air streams. Our dust collection blowers move air at under fifty miles an hour while our blades, bits and cutters often launch dust at over one hundred miles an hour. If our hoods don't block, control and capture these dust filled fast moving air streams, we lose. Most traditional tools spray dust filled air streams all over and the cost to remake our tools is prohibitively expensive, but using the same improved hoods required for good chip collection also helps resolve the problems for good fine dust collection. Again the experts have shared their designs for hoods that work well and the Ducting page here shows what you need.

The top dust collection firms share their decades of experience to show us exactly how much air we need to move at almost every size and type of tool. Their tables show it takes almost exactly three times more total airflow to pull in the fine dust than it does to collect sawdust and chips. This requirement does not seem to make sense because it takes moving a lot more air to pull in the fine dust that we can move with the lightest breath. The problem is fine dust is so light that normal room air currents will blow it all over unless we capture it before it escapes. Many wrongly think our powerful dust collection systems will easily pull in this fine dust and they will, but with a problem which we already understand. Our shop vacuums on blow will move stuff all over the shop, yet on suck we have to get the nozzle right next to what we want to collect or we get nothing. In college a professor gave us soda straws and told us to try to move a balloon by blowing and sucking without touching. You can easily blow a balloon all over, but it is near impossible to move by sucking. Unlike blown air that will hold together for a long distance, sucked air comes from all directions at once so air speed drops off at roughly 12 times the distance squared (4*Pi*r*r). So the problem is our powerful dust collection systems suck so airspeed falls off so quickly they cannot collect the fine dust before normal room air currents blow the fine dust all over. The experts found in addition to good hoods that manage the fast moving air streams, we also must surround each tool with a large low pressure area or "bubble" around the working areas of our tools. The air speed inside this bubble must be at least fifty feet per minute out to fifteen and a quarter inches in all directions or normal room air currents will blow the fine dust all over before it can be collected. It takes a lot of air to build a bubble big enough to pull in the fine dust ample to pass EPA air quality tests, right at 1000 cubic feet per minute (CFM) at each small shop stationary tool.

Blower technology is mature meaning professional commercial blowers of the same size, type, and speed move very close to the same air regardless of which major name blower we buy. Unfortunately, lots of testing shows other than Jet and Delta, most small shop blowers are not well made so move much less air. This means the commercial blower tables show the maximum we can get, not what we will really get. How much air our blower moves depends upon how much resistance we have in our system. This resistance is known as static pressure. Static pressure includes the airflow losses with our tool hoods, losses from duct and flex hose friction, overhead to run our system and the overhead to push air through our filters. It takes a lot of extra work to force air in the tight separation spirals inside our cyclones, so that overhead requires a bigger more powerful blower. The commercial blower tables show at normal static pressure resistance levels it takes a 3 hp dust collector or 4.2 hp cyclone to move our needed 1000 CFM assuming a clean filter and amply sized ducts. Because 4.2 hp motors are not readily available, most need 5 hp motors to power their cyclones.

Air at dust collection pressures will compress little more than water, so any plugged filter, undersized duct, rough duct component, etc. can greatly reduce our airflow similar to a partially closed water valve. In fact, testing by the top name in air quality test equipment, Dwyer Instruments shows just ten diameters of any sized duct will limit the air flow. The air equation shows that with normal dust collection blower pressures we need all 7" or larger diameter duct to move our full 1000 CFM. Without this much airflow, woodworking makes so much dust that even venting outside misses collecting considerable dust. With my systems I increase the impeller size to increase pressure enough to permit moving over 1200 CFM through a 6" duct because 7" duct and fittings are too hard to find and too expensive.

And, we have to get rid of the fine dust. The experts found that woodworking makes so much fine dust that trying to use fine enough filters to protect our health means we must replace our expensive fine filters every three months or so. Rather than mess with constantly cleaning and replacing large expensive filters, most larger facilities first use fairly open filters to pull off the larger particles then vent the remaining fine airborne dust outside where it quickly dissipates without a trace. This is the preferred method.

-

Chip Collection